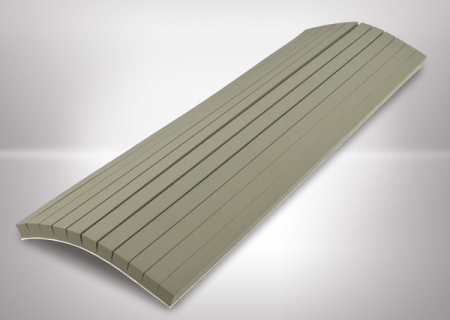

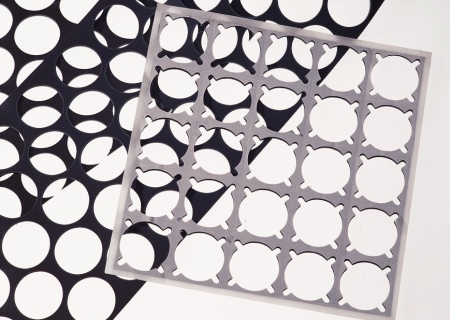

Fabricated Foam Gaskets

Closed cell foam, sponge rubber, and even open cell foam materials have been used for gasketing applications for years at Insul-Fab. It was one of our founding product lines over 30 years ago. Our vertically integrated manufacturing capabilities can split foam to thickness, coat and laminate adhesives, slit rolls to width, and then die cut, kiss-cut, or water jet cut parts to specification.

The number of material options available can be daunting, but Insul-Fab sales engineers can help specify the right product for each application based on needs for compression deflection, compression set, temperature, flammability, oil resistance, UV resistance, and density.

Fabricated Foam Gasket Information Summary

- Neoprene (CR) and neoprene blends, PVC, vinyl/nitrile (PVC/NBR), polyethylene, EPDM, polyurethane, and more available in stock for quick turn gaskets.

- Vertical integration of capabilities provides splitting, adhesive lamination, roll slitting, spooling, die cutting, thermoforming, and water jet cutting.

- In-house coating provides very economical adhesive backing options.

Brand name foams we offer for gaskets include Armacell, Monarch®, Ensolite®, Oletex®, Volara®, K-Tek®, Rogers Poron®, Rogers Bisco®, Nomaco, and American National Rubber. For legacy products and those that are hard to find such as Rubatex, we offer alternatives and corresponding technical data.

Applications of Foam Gaskets

- HVAC and appliances

- Cabinets and enclosure seals

- LED Display Gaskets

- Medical devices

- Oil and gas equipment

- Automotive and Transportation Equipment

- Military hardware

- Aircraft and Aerospace

Custom Foam Gasket Product Information

- Foam Products Brochure (PDF)