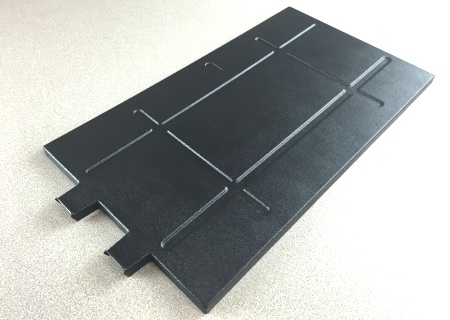

Thermoformed Plastics

Vacuum and pressure thermoforming offers the ability to make a wide variety of parts from sheet, film and foam thermoplastics. Our range of forming equipment and trimming capabilities, matched with an ISO 9001 and AS9100 registered quality program provides an excellent choice for customers looking for custom formed plastic solutions.

Insul-Fab specializes in the material selection and design support of thermoforming components with regards to temperature resistance, strength, flammability, cosmetics, durability, and cost. Most thermoforming molds and trim fixtures are produced in-house for fast turnaround and reduced expense.

Thermoformed Plastic Product Summary

- Formed plastic parts with low to moderate tooling costs compared with other technologies.

- 30 years of expertise in thermoforming and trimming custom applications.

- Thermoformed plastic sheet, film, foam, and non-woven fiber made from ABS, PVC, PETG, styrene, polyester, polycarbonate, Kydex (acrylic/PVC), and polyethylene can be thermoformed.

Applications of Thermoformed Plastic Products

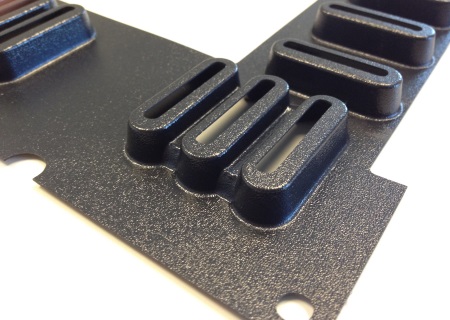

- Covers and panels for vehicle interiors and cargo systems

- Enclosures for acoustic insulation on noisy equipment (see Acoustic Insulation Covers)

- Formed thermal insulation for heat exchangers and chilled water valves (see Thermal Insulation Covers)

- Thermoformed plastic trays and reusable packaging products

- Directional air flow channels in electronics (see Thermal Control Products)

- HVAC Equipment and commercial appliances