PORON® 4701-60 : “Very Firm” Polyurethane

Poron® grade 4701-60 foam is a “very firm” grade foam material for energy management and high closure force gasketing needs. The unique cellular properties allow for consistent closure force and very limited stress relaxation and compression set in sealing, cushioning, and gap filling applications.

FEATURES

- Resistance to Stress Relaxation and Compression Set

- Vibration and Impact Energy Absorption

- Low Outgassing

- Broad Service Temperature Range

- Flame Retardant

- Fabricates by Die Cutting, Water Jet, and Laser

- Consistent Thickness and Cell Structure

- RoHS Compliant

- Excellent Technical Assistance and Sample Support

DETAILS

PORON® grade 4701-60 open cell polyurethane foam is a firm grade material for energy management and high closure force gasketing applications . It is offered in three densities (15, 20, and 25 lbs/ft3) providing a range of properties within the product family. The standard available thicknesses range from 0.031" to 0.250" (0.79 mm to 6.35 mm).

| Property | Value | ||

| Density, lb/ft3 (kg/m3) | 15 (240) | 20 (320) | 25 (400) |

| Thickness, in (mm) | 0.125-0.250 (3.18-6.35) |

0.031-0.188 (0.79-4.78) |

0.031-0.093 (0.79-2.36) |

| Compression Force Deflection, psi @ (25%) | 18-50 | 25-85 | 50-130 |

| Hardness, Shore “O” | 42 | 55 | 63 |

| Compression Set, max % | 5 @ 23oC 10 @ 70oC |

||

| Service Temperature, Continuous, oF (oC) | High: 194oF (90 oC) Low: 3 oF (-16 oC) |

||

| Flammability, UL 94HBF, @ in thickness (File E20305) |

>0.125 | >0.062 | - |

| UV Resistance | “Good” | ||

| Color | Black | ||

| Material Width, in | 54 | ||

| Format Availability | Fabricated Parts, Foam Tapes, Rolls, Sheets | ||

| Thermoformable | No | ||

| RoHS Compliant | Yes | ||

| Halogen Free | No | ||

| INSUL-FAB PN | Varies – See Availability Chart | ||

| Supplier Data Sheet | PORON® 4701-60 “Firm" Data Sheet | ||

PORON® microcellular polyurethane products are fine pitch open cell foams produced by Rogers Corporation. Their unique properties allow for consistent closure force and very limited compression set in sealing, cushioning, and gap filling applications.

Elevated temperature is used to simulate accelerated aging, indicating long-term performance of Rogers PORON® compared to other common foam products used in gasket and seal applications.

In addition to grade 4701-60 “Very Firm”, they are available in a variety of product types from 0.012" (.30mm) to 0.500” (12.7mm) thick for converted applications in sealing, cushioning, and gap filling. Click here for a full listing of PORON® products.

Insul-Fab is proud to be designated a Major Converter for Rogers Elastomeric Materials Solutions (EMS) and we commonly have many of their standard products in stock for fabrication. Our expertise in material fabrication and supporting OEM design and production applications spans over 50 years of serving a wide variety of markets.

Insul-Fab is proud to be designated a Major Converter for Rogers Elastomeric Materials Solutions (EMS) and we commonly have many of their standard products in stock for fabrication. Our expertise in material fabrication and supporting OEM design and production applications spans over 50 years of serving a wide variety of markets.

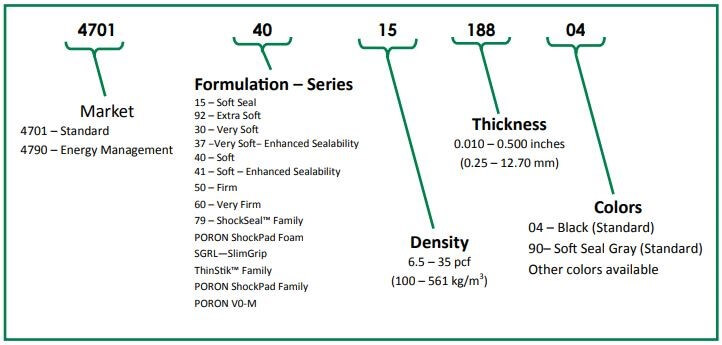

Product Identification System

PORON® products are made in with varying density, thickness, sealing capability, compression recovery, and construction characteristics. Unlike many other foams, PORON® is made to intended end-use thickness with a skin on both sides, rather than being skived down from a thicker bun or roll which exposes the cell structure but allows more thickness flexibility. As a result, typical part drawing specifications call out a PORON® product identification.

Standard Product Availability

Within the most common PORON® product lines there are many SKUs that are available as standard, and many more that are non-standard but available with minimum orders. A listing of these products is shown below. Please note, this information is subject to change.

| PORON® 4701-60: Very Firm | |||

| Product | Density (lbs/ft3) | Thickness (in) | INSUL-FAB PN |

| 4701-60-15188-04 | 15 | 0.188 | - |

| 4701-60-15250-04 | 15 | 0.25 | - |

| 4701-60-20031-04 | 20 | 0.031 | - |

| 4701-60-20062-04 | 20 | 0.062 | 1774 |

| 4701-60-20125-04 | 20 | 0.125 | 2907 |

| 4701-60-20188-04 | 20 | 0.188 | - |

| 4701-60-25031-04 | 25 | 0.031 | - |

| 4701-60-25062-04 | 25 | 0.062 | - |

| 4701-60-25093-04 | 25 | 0.093 | - |

Click here for a complete listing of PORON® product availability or contact us to find out if the PORON® SKU you are looking for is available in stock. Samples of any of the materials are generally available within 1-3 days of request.

In applications where the desired thickness is not available, Insul-Fab can laminate two layers of PORON® together with adhesive, or we can utilize another substrate, such as Formex or Lexan plastic film, to fill the desired gap and provide part rigidity while maintaining a stack-up of UL rated products for flammability requirements.

Adhesive Backing and Lamination

Most applications for Rogers PORON® Polyurethanes require an adhesive backing with release liner for attachment in the end use, or as an assembly aid. Insul-Fab laminates PORON® materials using pressure sensitive adhesives. PORON® does not contain plasticizers, like many other foam products do, so long term bond strength is maintained. While many products bond well to PORON®, we recommend the following laminating adhesives.

| Adhesive | Construction |

| 3M 467MP and 3M 468MP | .002” and .005” unsupported acrylic |

| 3M 9832 and 3M 9832HL | .005” double-coated acrylic |

| Concote CC593 | .004” double-coated acrylic |

Adhesive selection should be influenced by the end-use attachment substrate, the configuration of the part, and the application use conditions. Unsupported acrylic adhesives offer an excellent bond and ability to conform to surface variations. Double-coated or supported acrylics provide dimensional stability to larger parts or thin cross sections, to prevent stretching during end use application.

Other applications require the addition of a laminated film for surface protection, cosmetics, dimensional stability, or surface sliding. We have available films such as PET, Formex, and Lexan for these occasions.

Applications

- Environmental Seals

- Foam Tapes

- Motor & Fan Mounts

- Vibration Isolation & NVH

- Gaskets

- LED Light Seals

- Air Gap Filling for Thermal Management

- IP Rated Enclosure Door Seals

- Battery Support Pads

- Spring / Rebound Pads

- Appliance Foot Pads & Anti-Slip

- Sound Damping

- Transportation Interiors

- Cable Grommets & Pass-Throughs

PORON® is an ideal material for many applications for air, dust, or light sealing. Despite being open cell, it can also be used effectively for moisture and water immersion gaskets and seals, with the proper material grade and compression.

Many Rogers PORON® products carry a UV Resistance rating of “good”, per ASTM G 53-96, but we do not recommend them for extended use in direct sunlight applications. For options, consider materials we offer made from silicone or EPDM.

For assistance choosing the right PORON® material for your application, try the interactive PORON® Product Properties Guide.

Resources

Brochures & Literature

Tools

Related Links

Similar or related products

- Complete line of PORON® materials

- Rogers Bisco® Silicone materials

- Griswold Enlighten-u®

- St Gobain Norseal® Microcellular PUR Foam

- 3M™ Bumpon™ Resilient Rollstock

The Rogers logo and PORON® logos are trademarks of Rogers Corporation or one of its subsidiaries. © 2019 Rogers Corporation.

The technical data provided on this page is intended to assist you in material selection. It is not intended to and does not create any warranties, express or implied. The user should determine the suitability of the material for each application.